Get Your Free Quote…!

All pumps are tested, inspected and protected against corrosion for the period of shipment and installation .If the pump is not to be installed at once, the pump, parts and accessories, etc., should be stored in a clean, dry location, free from temperature extremes, in an approximately level position and without distortion. Slush all machined surfaces with noncorrosive oil, inspect frequently to see that the surfaces are free of corrosion.

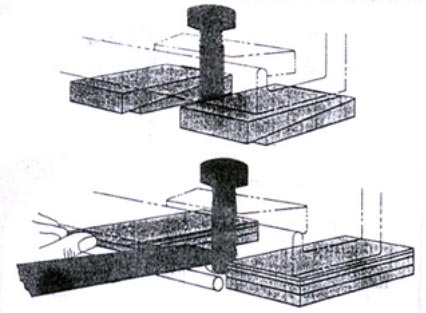

The foundation should be sufficiently substantial to absorb vibration and to form a permanent, rigid support for the base plate. This is important in maintaining the alignment of a direct connected unit. A concrete foundation on a solid base should be satisfactory. Foundation bolts of the proper size should be embedded in the concrete, located by a drawing or template. A pipe sleeve larger than the bolt should be used to allow movement for final positioning of the bolts.

Make sure that the concrete foundation has set firmly before placing the base frame along with the pump set or pump on it. The surface of the foundation should be truly horizontal and perfectly flat. The foundation bolts should be suspended in the base plate.

When the alignment is correct the foundation bolts should be tightened evenly but not too firmly. The unit can then be grouted to the foundation. The unit can then be grouted to the foundation. The base plate should be completely filled with grout, and it is desirable to grout the leveling pieces, shims or wedges in place. Foundation bolt should not be fully tightened until the grout is hardened, usually about 48 hours after pouring.

When the unit is received with the pump and the driver mounted on the base plate, it should be placed on the foundation and the couplings halves disconnected. The coupling should not be reconnected until the alignment operations have been completed. The base plate should be supported on rectangular metal blocks and shims or on metal wedges having a small taper. The metal pieces should be placed close to the foundation bolts

On large units, small jacks made of cap screws and nuts are very convenient. In each case the supports should be directly under the part of the base plate carrying the greatest weight and spaced closely enough to give uniform support. A spacing of 24 inches is suggested on medium size units. A gap of about ¾ inches to 1.5 inches should be allowed between the base plate and the foundation for grouting.

Adjust the metal supports or wedges until the shafts of the pump and driver are level. Check the coupling faces as well as the suction and discharge flanges of the pump for horizontal or vertical position by means of a level. Correct the positions, if necessary, by adjusting the supports or wedges under the baser the plate as required.

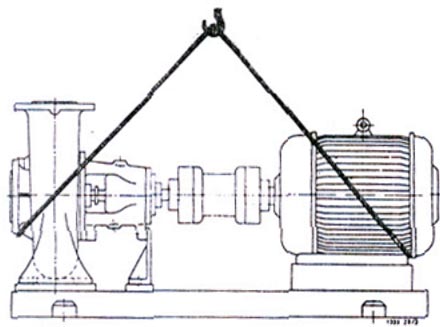

The pumping set should be properly handled and slung for transport . Do not thread the ropes the eye bolt on the motor

During handling do not remove the rubber blanking provided on the suction and discharge nozzles

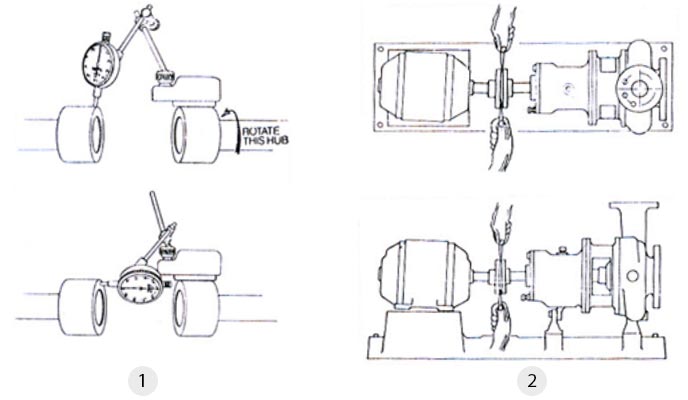

The following discussion of alignment applies primarily to horizontal, general service, centrifugal pumps driven by an independent driver through a flexible coupling and with pump and driver mounted on a common base plate.

Pumps and drivers that are received from the factory with both machines mounted on a common base plate were actually aligned before shipment. All base plates are flexible to some extent and, therefore,must not be relied upon to maintain the factory alignment. Realignment is necessary after the completeunit has been leveled on the foundation and again after the grout has set and foundation bolts have been tightened. The alignment must be checked after the unit is piped and rechecked periodically as outlined in the following paragraphs. To facilitate accurate field alignment, most manufacturers either do not dowel the pumps or drivers on the base plates before shipment, or at most, dowel the pump only.

There are two forms of misalignment between the pump shaft and the driver shaft, as follows:

Angular misalignment: shafts with axes concentric but not parallel.

Parallel misalignment: shafts with axes parallel but not concentric.

Pipes must line up naturally. They must not be forced into place with flange bolts, as this may force the pump out of alignment. Pipe should be supported independently of pump so as not to produce anystrain.

The pump branches should not absorb pipe forces and moments, the pump must not be used as a locating point of the pipe work. After connecting up the piping, the coupling alignment must be rechecked. It must be possible to turn the rotor easily by hand. In case of in- adequate alignment, bearings, coupling, shaft seal, and impeller wear rings may got damaged prematurely. In accordance with legal prescriptions the coupling must be protected with a guard against contact.

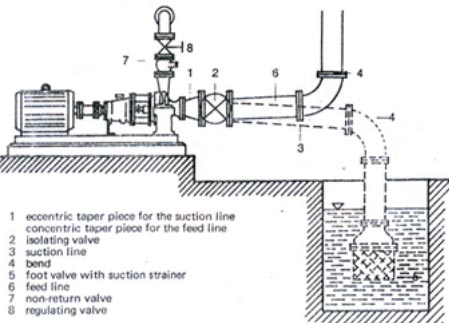

To prevent collection of air the SUCTION LINE must be horizontal or rise continuously all the way to the pump. The FEED LINE, however, must be horizontal or show a gradual slope towards the pump. The suction line must be completely airtight and laid so that it can be properly vented (Fig : 5.). If tapers are required, eccentric ones must be used. The inlet bore of the suction pipe should be set as deeply as possible below liquid level and be provided with a foot valve fitted with a suction strainer.

The foot valve must, however, be far enough away from the bottom to avoid inlet losses becoming too great and there by lowering the performance.

The isolated valve in the suction or feed line must remain fully open during the operation and n and must never be used for regulating. They should be mounted with the spindle in the horizontal or in the vertical downward position to avoid air pockets forming in the spindle cap.

To avoid ingress of air, it is advisable to use isolating valves with sealing water connection or with a water seal.

Install gate valve or an output control valve in the delivery line as close to the pump branch as possible. It is recommended to install a non return valve between pump branch and regulating valve, thus protecting the Pump against reverse rotation and further more the pump and the foot valve against water hammer which may occur in case of sudden shut down.

IFor the sealing liquid line connection (s) please refer to the arrangement drawing. The service data (like pressure, flow rates, etc.) for external sealing are stated in our operation manual. If only sealing liquid INLET is provided for a regulating valve is to be installed in the line. If an INLET AND OUTLET line (discharge in to open air) are provided for, the regulating valve is to be fitted in the discharge line.

For the cooling water line connections please see the arrangement drawing. Connect the cooling water line so that the inlet is at the lower connection, thus ensuring that the cooling chamber is vented and completed filled.

For the heating line connections see the arrangement drawing. The service data (like pressure, temperature, flow rates, etc.) are given in our operation manual.

If steam is employed for heating, the inlet should be provided on the top that the condense may flow off through the outlet at the bottom.

In the event of liquid being used for heating, the inlet should be provided at the lower connection, thus ensuring that the heating chamber is vented and completely filled.

For the cooling water line connections please see the arrangement drawing. Connect the cooling water line so that the inlet is at the lower connection, thus ensuring that the cooling chamber is vented and completed filled.

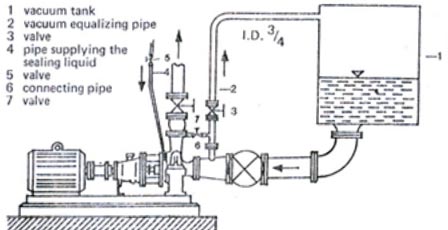

If the pump draws from a system under vacuum, an equalizing pipe must be must be carried from the highest point of the suction line, however, as close to the suction branch as possible, to the top of the feed tank to keep gas bubbles that might have been entrained in the flow from entering the pump

The line should be fitted with an isolating valvewhich should be closed only for maintenance work on the pump set. Apply sealing liquid (external sealing) to the shaft seal to prevent entry of air.