Get Your Free Quote…!

Ronak enjoys an enviable reputation as being one of the leading suppliers of Mechanical Sealing System.

We at Ronak Sealing offer complete Mechanical Seal Care Solution. Our products are customer oriented and designed as per cus¬tomized service programs and flexible service for seals and gaskets. The service port¬fo¬lio extends from con¬sult¬ing and en¬gi¬neer¬ing, via a range of main¬te¬nance services through in¬di¬vid¬u-ally-tai¬lored service. We understand the requirements of process industries, and have in-depth knowledge, expertise and technical skills to serve our customers at their location.

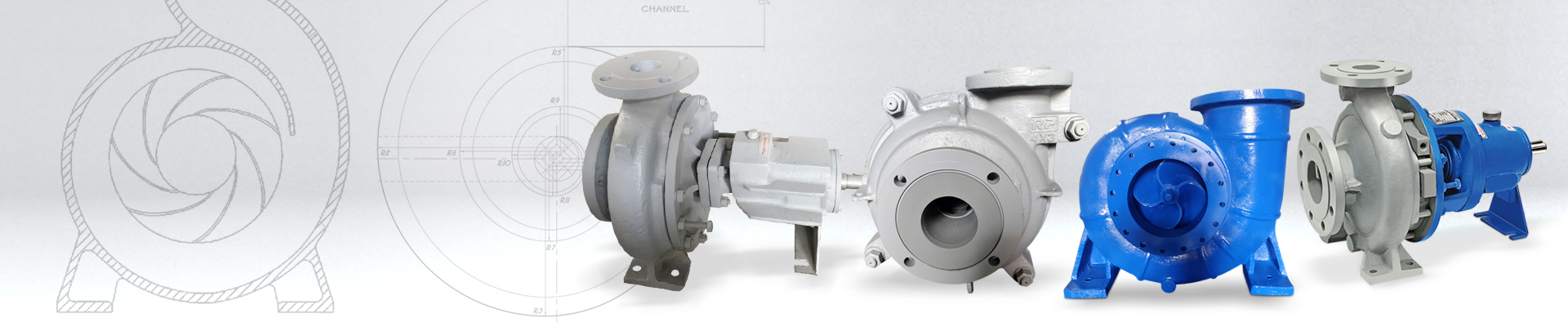

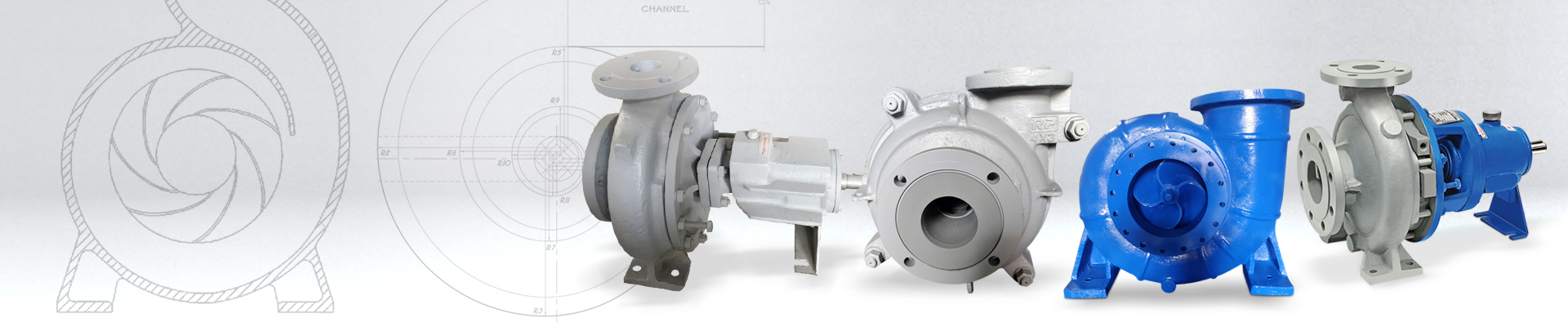

Mechanical seals act as leakage prevention for the Centrifugal Pumps. The most effective method of preventing the leakage of the fluid from the centrifugal pump to the external surroundings is using the mechanical seals. The mechanical seals help sealing the rotating part of the shaft against the stationary part of the pump housing.

The mechanical seal acts as a check valve and a slider bearing. The obvious function of a check valve is to prevent liquid under pressure from leaking out of the pump, or from drawing air into the pump when under vacuum conditions.

Since the seal must function as a slider or friction bearing, the seal has an unpredictable life span. The seal of a centrifugal pump is usually replaced many times during the life of a pump. All bearings need lubricant and the seal lubricant is the liquid which is pumped. Liquid infiltrates between the contact faces of the primary and mating rings. Some of this liquid does find its way through to the atmosphere and is so slight that is only noticeable as corrosion of build-up on the pump adapter. The condition of the pumped liquid greatly affects the seal life.

The most dangerous element for mechanical seal is abrasive particles in the liquid being pumped. Abrasives may be anything from dirt to dissolved impurities in the liquid precipitating out of solution. These abrasive particles infiltrate with the liquid between the seal faces and grind away the carbon primary ring, the normal shiny face of the primary ring and mating ring becomes dull due to this problem.

Excessive heat can damage the seal in two areas - the primary ring and the elastomeric parts. The primary ring is made primarily of carbon. Should the pump be operated without liquid - even for a very short period of time - the primary and mating ring faces are denied lubricant. This causes the faces to become very hot. The binder mixed with the carbon breaks down and the face of the primary ring turns to a dull black powder. The O-ring, or cup, and flexible diaphragm of the seal are made of one of many types of rubber-like substance called an 'elastomer'. The type of elastomeric material is hence specially selected to match the temperature limit and types of material being pumped. Should the temperature limit exceed, the diaphragm and O-ring will become hard and sometimes develops crack and seal will then starts to leak.

Mechanical seals are manufactured using three basic sets of parts. Each seal will have a set of primary seal faces, a set of secondary static seals, typically O-rings, wedges and, or, V-rings, and a spring to maintain face contact. The most common methods of energizing the seal faces include a single spring, multiple springs or metal bellows.

Excessive heat can damage the seal in two areas - the primary ring and the elastomeric parts. The primary ring is made primarily of carbon. Should the pump be operated without liquid - even for a very short period of time - the primary and mating ring faces are denied lubricant. This causes the faces to become very hot. The binder mixed with the carbon breaks down and the face of the primary ring turns to a dull black powder. The O-ring, or cup, and flexible diaphragm of the seal are made of one of many types of rubber-like substance called an 'elastomer'. The type of elastomeric material is hence specially selected to match the temperature limit and types of material being pumped. Should the temperature limit exceed, the diaphragm and O-ring will become hard and sometimes develops crack and seal will then starts to leak.

Pump seal in a centrifugal pump from a Sentra mold temperature controller.