Get Your Free Quote…!

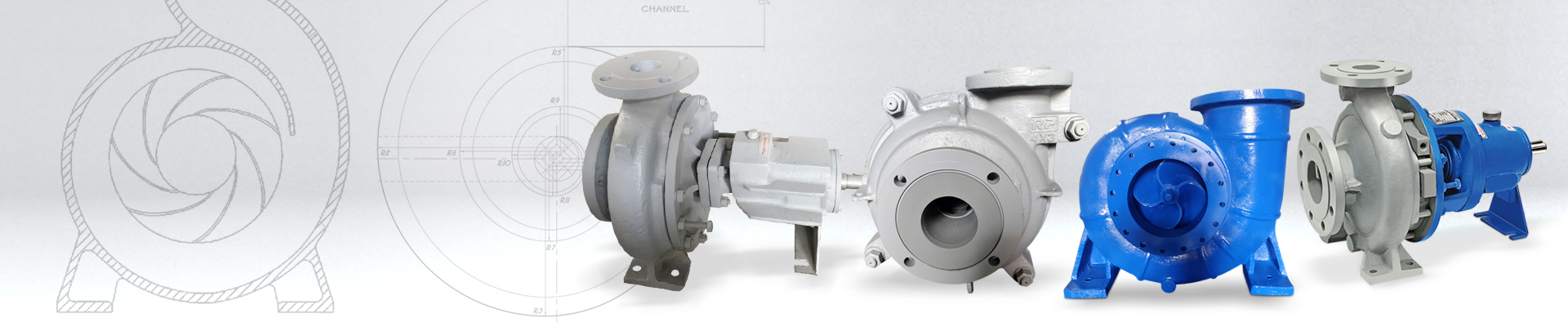

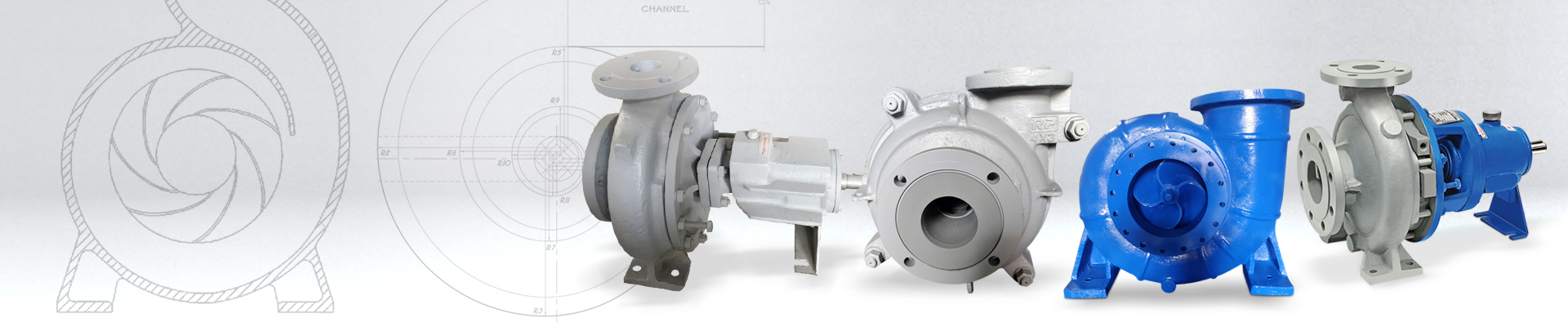

The SMF series are single‐stage centrifugal pumps suitable for handling pure or contaminated liquids in large quantities. These pumps are of robust construction and have long working life. These pumps are also low in energy consumption due to very good efficiency. The precision machined pump shaft is seated in amply oil/grease lubricated and protected by a shaft sleeve in the stuffing box area. The integrally cast feet of the casing transmit any forces originating from the pipe work directly to the foundation, this means that the rotor is not subjected to any bending stresses and thus optimal working life of the bearings is assured. Electric motors can be used as the prime mover. With diesel engine as the prime‐mover, the pump’s direction of rotation is anticlockwise from the driven and.

SMF Pumps are normally recommended for clear cold water having turbidity maximum 50 ppm (Silica Scale), chloride maximum 550 ppm. Total solids 3000 ppm. PH value between 6.5 and 8.5 and specific gravity around 1.0 SMF pumps can be offered for liquids having viscosity upto 1000 SSU.

These are three / four vane impeller pumps (in standard pump) specially designed to pass solid or stingy material. Hand hole are provided in the casing and near the throat of impeller. Pumps are available in horizontal & side discharge construction, vertical dry pit or wet pit construction with motor directly mounted on the pump or at an elevation and connected through intermediate shaft.

Casing: Pump casing is high strength cast iron with ample section thickness to product a large factor of safety over the maximum allowable working pressure. The casing is enclosed by a suction and stuffing box cover or head carefully machined to assure perfect alignment. Suction and discharge nozzles and the supporting feet are cast integral with the casing. All Flange are drilled according to BS 10 table D. Drilled as per DIN/ASA is also possible on specific request.

Impeller: The Impeller of SMF pumps are made of SS 304 (in standard pump). The impeller is semi‐ open type having passages into which passages into which the liquid flows direct and unimpeded. The impellers are provided with balancing holes for balancing the axial thrust. They are also dynamically balanced to counter the vibrations. Impellers in other materials such as close grained cast iron, bronze, phosphors bronze Ni‐cast iron, cast steel etc. are also available on request.

Bearing Housing Assembly:The rotating assembly is supported on heavy duty bearings mounted in a precision bored frame. Bearing are carefully sealed to exclude moisture and contaminants and retain lubricant.

Stuffing Box: Extra deep design and features a gland to simplify replacement of gland packing. Packed stuffing box with lantern rings is the standard arrangement. It is sealed internally. However, against special requirement, sealing by external fluid is also provided.

Shaft: Machined from high quality steel, the shaft is sturdy design to minimize deflection and provide long reliable service. Shaft is protected by sleeve from in stuffing box area.

Direction of Rotation: Clockwise viewed from the drive end.